The Varistor Production Equipment Is An Integrated Machine For Testing, Marking, Pin Cutting And Pin Pulling

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | SGS.UL |

| Model Number: | LJYT-B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 5-7 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 5000,000,000PCS Per Month |

|

Detail Information |

|||

| Highlight: | varistor production equipment integrated machine,metal oxide varistor testing marking machine,varistor pin cutting pulling machine |

||

|---|---|---|---|

Product Description

Varistor Testing, Marking, Cutting and Unplugging Integrated Machine

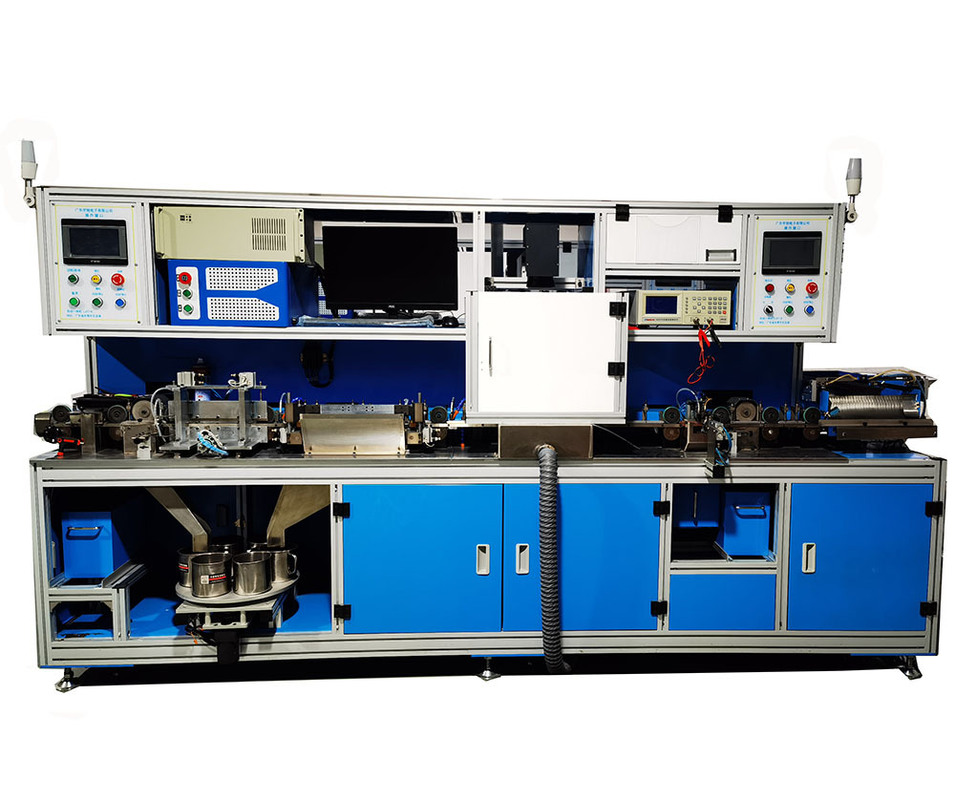

The Varistor Production Equipment is a fully integrated system for comprehensive post-production processing of varistors, combining testing, marking, pin cutting, and pin pulling operations in a single machine.

Model: LJYT-B

Key Features

- Complete integrated solution for varistor post-production processing

- Automated workflow from feeding to final packaging

- Precision testing with automatic defective product removal

- High-speed laser marking system (50W fiber vision marking machine)

- Efficient pin cutting and pulling mechanisms

- Built-in fault alarm and early warning system

Technical Specifications

| Parameter | Specification |

|---|---|

| Voltage | Single-phase 220V |

| Power | 3KW |

| Air Pressure | 5-6 kg |

| Production Efficiency | 15-18KPCS/H (single-sided testing) |

| Construction | Aluminum profile frame with sky blue painted panel |

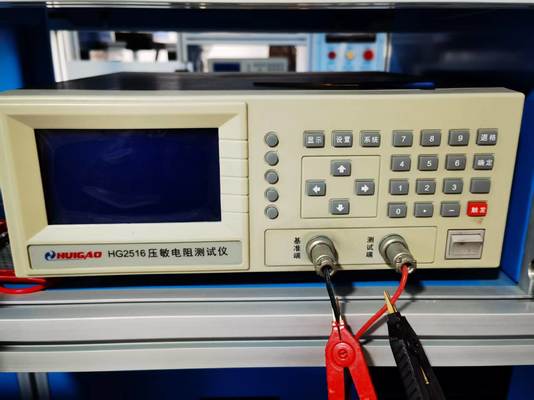

| Test Instrument | Huigao HG2515 |

| Continuous Operation | 24 hours non-stop capability |

Operation Process

- Manual feeding to material trough

- Automatic feeding system

- Tail ring cutting

- Test Station 1 (sliding test with automatic defective product removal)

- Single-sided laser marking

- Pin pulling, counting and packaging

- Insulation pin alignment

- Short pin cutting, counting and packaging (circular knife cutting)

- Waste wire pulling mechanism

- 10-position turntable material collection

Laser Marking System Specifications

- Laser Power: 50W (special wavelength customization available)

- Scanning Speed: ≥300 pieces per minute

- Marking Range: 400mm * 450mm

- Passage Width: 14.5mm (Y-direction paper tape width)

- Positioning Tape Spacing: 320±1.5mm

- Quality Assurance: Static marking with no deformation, missing characters, double images, or deviation

Mechanical Features

- Sliding measurement design with adjustable test time

- Product positioning by fiber optic amplifier with reversible lift control

- Defective product removal via mechanical claw design (dual cylinder system)

- Vacuum suction feeding with push plate output material collection

- Motor crankshaft circular operation for automatic feeding

- Photoelectric sensing control for precise operation

- Upper/lower circular knife cross design for tail cutting (adjustable knife seat)

Want to Know more details about this product