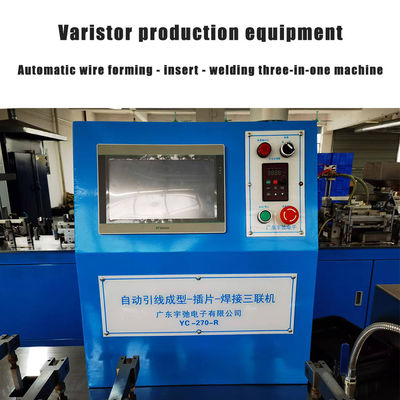

The Automatic Production Machine For Varistors Features An Automatic Three-in-one System For Wire Forming, Chip Insertion And Welding

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | SGS.UL |

| Model Number: | YC-270-R |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 5-7 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 5000,000,000PCS Per Month |

|

Detail Information |

|||

| Highlight: | automatic varistor production machine,three-in-one varistor welding system,metal oxide varistor manufacturing equipment |

||

|---|---|---|---|

Product Description

Automatic Production Machine For Varistors

Features an automatic three-in-one system for wire forming, chip insertion and welding.

Basic Operation Process

- Wire feeding section and motor belt feeding

- Straight wire feeding

- U-shaped cutting

- Punching

- Driven by the embossing wheel of the wire divider

- Wire alignment

- Flattening the long arm

- Floating foot position 1

- Floating foot position 2

- Parallel foot position

- Gold mold forming

- Tensioning before inserting pieces

- Driven by the needle wheel of the wire divider

- Buffering

- Applying solder

- (Blowing and drying) natural drying

- Inserting pieces

- Driven by the needle wheel of the wire divider

- First preheating zone

- Second preheating zone

- Dip welding

- Step drive

- Natural cooling buffer

- Buffer

- Step drive

- Cutting

- Buffer frame

Technical Parameters and Requirements

| Machine Dimensions | 10 meters long, approximately 1,500 kg weight |

| Machine Model | YC-270-R |

| Product Pitch | 10mm |

| Aperture | 2.5mm 28 single-row paper tape products |

| Production Efficiency | 180-260pcs/min (Pitch10) |

| Ceramic Tile Size | Diameter: 7D, Sheet thickness: T≤3.5mm |

| Lead Wire Specification | φ0.56mm |

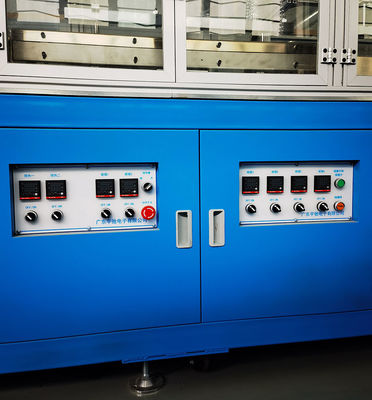

| Power Usage | AC380V, 50HZ; Air source: 5kg/cm; Total power approximately 16KW |

| Warranty Period | One year (excluding human factors and natural disasters) |

Additional Technical Specifications

- Wire feeding mold: 0.56 specification mold (on assembly table)

- Maximum length of paper tape for wire feeding: 35mm

- U-shaped mold width: F5mm (1 set installed on machine)

- Alignment mechanism: Five sets of V-shaped bearings (13 in each set)

- Paper tape size: Three-in-one paper tape 14.5x0.85mmx1000m

- Machine equipped with two sets of forming mechanisms: floating feet and parallel feet

- Flux application with flow detection switch to prevent empty welding

- Preheating tanks: Two groups (each 896mm long)

- Dip soldering tank with three heating units

- Machine frame: Welded plates with blue baked paint panel

- Noise reduction design with spiral bevel gear and synchronous belt transmission

- Includes all vulnerable parts, spare parts and related component drawings

Equipment Schematic

Want to Know more details about this product