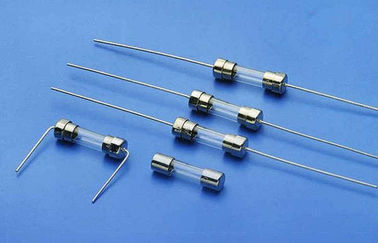

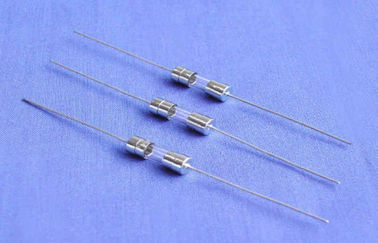

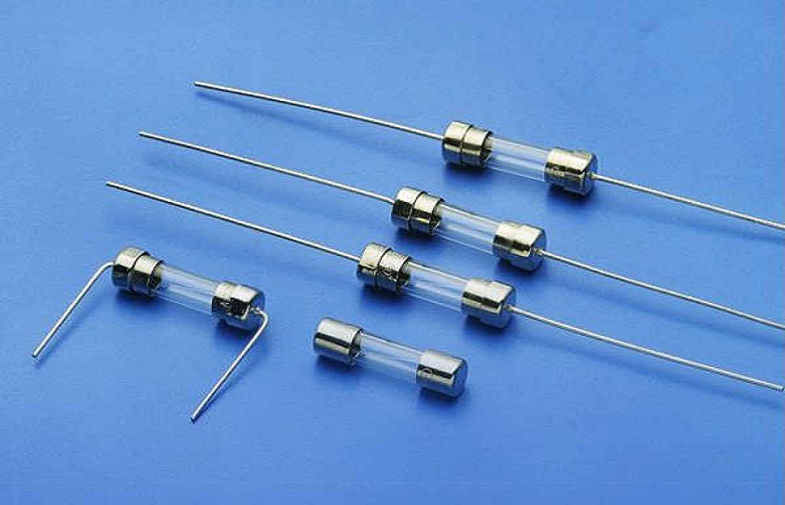

4 X 15mm UL 249-14 3A 350V Glass Fuses For Ballasts , Time-Lag Glass Fuse RoHS

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | UL |

| Model Number: | RTP300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000 PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk, 200PCS/Bag、10Bag/Inner Box、4Inner Box/Outer Box |

| Delivery Time: | 4-6 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 100,000,000PCS/Month |

|

Detail Information |

|||

| Highlight: | slow blow glass fuse,radial lead fuse |

||

|---|---|---|---|

Product Description

4 X 15mm UL 249-14 3A 350V Glass Fuses For Ballasts , Time-Lag Glass Fuse RoHS

Quick Detail:

Description:

RTP Series 3A 350V time-lag(slow blow) fuses are available in cartridge form or with axial leads. This series provides the same performance characteristics as its 3AG counterpart, while occupying one-third the space.

Applications:

Electronics Lighting Ballasts

Specifications:

1. Applicable Scope

|

number |

volltage |

current |

approval number |

|

1 |

250V |

1A~3.15A |

CQC11012061981 |

|

2 |

250V |

500mA ~5A |

CQC11012058774 |

|

CQC11012061982 |

|||

|

3 |

250V |

1A ~3.15A |

40034581 |

|

4 |

250V |

500mA ~5A |

40032053 |

|

5 |

350V |

100mA ~10A |

E340427 |

![]()

|

numbers |

Parts name |

materials |

|

1 |

Lead wire |

Copper Plating Tin |

|

2 |

End cap |

Copper nickel plating |

|

3 |

ceramic tube |

ceramic |

|

4 |

Element |

Alloy wire |

|

⑤ |

Hot shrinkage |

Hot shrinkagetube |

|

Explain Lead wire: Lead only plays both ends an electrode and the role of the electrical properties of product can't afford function decomposition

Ceramic tube:To plays fixed and support

End cap: With 58% ~ 62% of brass for base, and nickel plating to prevent oxidation

Fuse elements: The key parts of the decided to fuse current specifications

1. Marking

The products lable in two end cap ,cap A and cap B, for the following schedule

For example

Cap A: Rated current+Rated volltage (100mA~10A) A Cap B:Type+manufacture’s logo+ Approved Symbol(optional) cURus 350V

The size of the words not defined,and must be very easy to read.

There shall not be any remarkable stain, rust or crack on the appearances.

2. Part of Testing

5.1 Mechanical characteristics

A. Tensile Test

When fuse is fixed and the tensile force 5N is applied in direction to lend.After the test, there shall be no remarkable damage to the fuses.

B. Thrust Test When fuse is fixed and the thrust 2N is applied in direction to lend.After the test, there shall be no remarkable damage to the fuses

C.Bending Test

Test Condition: Force 5N is applied; number of bends shall be one.After the test, there shall be no remarkable damage to the fuses.

2.2 Electrical characteristics

All tests are in the environment temperature 25 ± 5 ℃; Relative humidity45%~75%

5.2.1 Over load test

When the current in the following table is passing the fuse, its opening time must be in accordance with the requirements in the following table, that is, the pre-arcing time. Moreover, neither damage of the fuse-tube nor shattering of the cap shall occur. 5.2.2 Breaking capacity test

Rated breaking capacity:And after this test, there should be no damage of the fuse-tube or shattering of the caps. After this test, the insulation resistance between the end caps shall be not less than 0.1MΩ.

350V:Rated AC 100A

5.2.3 Temperature rising

At 100% times of rating electric current passes the fuse ,After reaching thermal balance, the temperature on the fuse surface rising is not higher than 75℃. |

|

Testing current |

Blowing time |

|

100% |

4 hours Min |

|

200% |

60 sec Max |

|

1000% |

10ms Min |

I-T Curve

![]()

I2T:Melting integral

|

Current |

I2T |

Current |

I2T |

|

100mA |

0.002 |

1.25A |

1.3 |

|

125mA |

0.003 |

1.5A |

1.6 |

|

160mA |

0.005 |

1.6A |

2.5 |

|

200mA |

0.01 |

2A |

5.8 |

|

250mA |

0.02 |

2.5A |

7.6 |

|

300mA |

0.04 |

3A |

8.1 |

|

315mA |

0.045 |

3.15A |

11 |

|

350mA |

0.055 |

3.5A |

19 |

|

400mA |

0.07 |

4A |

28 |

|

500mA |

0.1 |

5A |

40 |

|

630mA |

0.2 |

6A |

50 |

|

750mA |

0.35 |

6.3A |

64 |

|

800mA |

0.45 |

8A |

133 |

|

1A |

0.9 |

10A |

242 |

PACKING(reference, According to the requirement of packaging)

bulk 500 fuses per plastic- bag, 4 plastic- bags per inner box, 10 inner boxs per outer box.

In fact can be based on the customer orders requirements

Competitive Advantage:

1. Factory supply directly

2. Completed certificates such as UL,VDE,TUV,etc and high quality available

3. Quick delivery

4. Best after-sales services

-

OEM & ODM available

Certificates

![]()