6.35x32mm Time-Lag Glass 6A 250V Fuse / Electronics Fuses For Home Appliances

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | UL |

| Model Number: | 6N600AP |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk, 200PCS/Bag、10Bag/Inner Box、4Inner Box/Outer Box |

| Delivery Time: | 4-6 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 100,000,000PCS/Month |

|

Detail Information |

|||

| Highlight: | slow blow glass fuse,mini glass fuses |

||

|---|---|---|---|

Product Description

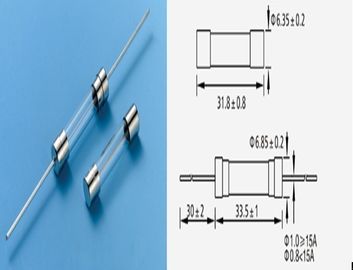

6.35x32mm Time-Lag Glass 6A 250V Fuse / Electronics Fuses For Home Appliances

Quick Detail:

1. Glass Tube Fuse

2. 350V available

3. Used for power supply,LED,CFL,PCB especially

4. Exact melting time

5. Stronger packing prevent damage when transport

6. Environmental Protection Material

Description:

Glass fuse is an electric element protecting electric devices. It is commonly connected with a circuit in series, and when fault current increases to a certain value, the fuse blows out to cut off the circuit so as to fulfill an aim of protecting other equipment in the circuit. The fuse is the most commonly used component in a over-current protection circuit. The traditional fuse mainly consists of two parts of a tube body, of which both ends have metal connecting terminals, and metal melt in the tube body. The majority of fuses are cylinder-shaped, namely cartridge construction. But nowadays, with the fast development of advanced technology, some special materials are well applied, the fuse industry has started to move forward in the direction of sub-miniature products and a series of new products such as Surface Mounted Devices type fuse are successively developed.

Applications:

Consumer electronics, mobile devices , home appliances, lighting appliances, power supplies and adapters, telecommunications equipment, solar electric power and industrial control equipment, etc .Glass fuse is suitable for all kinds of electrical products, It can have a current protection function.

Specifications:

1. The related standards and certification

1.1 Standards:UL248-1 UL248-14

2. Stracture and Dimension(Unit:mm)

|

|

3. Details of raw materials

|

No |

Name of parts |

Material |

|

1 |

End Cap |

Brass Surface Nickel |

|

2 |

Plated |

Ceramic |

|

3 |

Fuse Wire |

Alloy wire |

|

4 |

Lead |

Tin copper wire |

- Mark

4.1

The fuse brass cap are printed on the following sign:

1) A Cap:Rating current+Rating voltage

6A 250V

2) B Cap:Model + manufacturing plant trademark + the authentication symbols

UL

- Notice

Have no any rules for the size of mark..

6. appearance

The appearance should not have the stain and crack.

Mark should be easy to be identified.

7. Identify mechanical properties

7.1 tensile strength test

Fixing the fuse, bring to 5N axial tensile force on both ends of the lead, for 1 minute.

After the experiment, the fuse without any damage phenomenon.

7.2 Thrust test

Fixing the fuse,bring to 2N thrust by axial, for 10 seconds.

After the experiment, the fuse without any damage phenomenon.

7.3 Bending strength test(test conditions)

Bending test: Bending 90o with 5N force.

Bending back to count: reciprocating 1 back.

After the experiment, the fuse without any damage phenomenon.

8. Electrical characteristics

8.1 experimental conditions

All test environment temperature is 25 ℃ ±5.

8.2 load ability test

When the fuse through 100% of the rated current, It will not fusing within 4 hours.

8.3 Disjunction ability

The disjunction ability of fuse::10000A use 125V AC Power

35A use 250V AC Power(100mA~1A)

100A usd 250V AC Power (1.25A~3.5A)

200A use 250V AC Power(4A~10A)

8.4 The temperature rise test:

With rated current 1.0 times, when the temperature stability (5 minutes when measuring four times,

and each time the measurements and the average does not exceed 2 ℃). Test any part of the fuse body,the temperature rise can’t more than 75 ℃, the ambient temperature of 25 + 5 ℃.8.5

8.5 Time-current characteristics

|

Fuse Current |

Fusing Time |

|

100% |

4 hours Min |

|

135% |

120sec Max |

|

200% |

10 ms Max |

9. Environment characteristics

9.1 Using temperature range

-55℃~125℃.

9.2 Preservation conditions

Humidity: relative humidity ≦75% average can deposit in 3 years.

Competitive Advantage:

1. Factory supply directly

2. Completed certificates such as UL,VDE,TUV,etc and high quality available

3. Quick delivery

4. Best after-sales services

- OEM & ODM available

Certificates

![]()