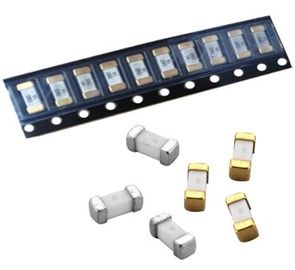

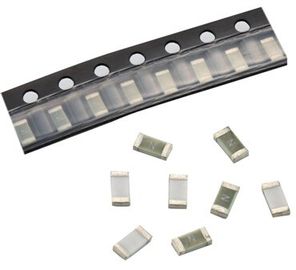

Large Current 60A Slow Blow Fuse , Ceramic Chip Fuse R1032 RoHS Compliant

Product Details:

| Place of Origin: | DONGGUAN,CHINA |

| Certification: | UL,CUL |

| Model Number: | R1032 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10,000PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Tape in reel |

| Delivery Time: | 7 days |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 10,000,000pcs per week |

|

Detail Information |

|||

| Product Name: | Chip Fuse | Series: | R1032 |

|---|---|---|---|

| Dimension: | 3.1*10 | Rated Voltage: | 75V 125V 250V |

| Agency Approval: | UL,cUL | Rated Current: | 0.05~60A |

| Operating Temperature: | -55°C ~125°C | RoHS Compliant: | Yes |

| Halogen Free: | Yes | Body: | Ceramic |

| Fuse Element: | Cu-Ag Alloy Wire | Cap: | Au Plated Brass Cap |

| Package: | Tape In Reel | MOQ: | 2000PCS Per Reel |

| Highlight: | slow blow glass fuse,mini glass fuses |

||

Product Description

UL Certificated Large Current 60A Max. 75V 125V 250V R1032 Time Lag Chip Fuse

PDF Specification Datasheet : UL Certificated Large Current 60A Max. 75V 125V 25...

Overview

R1032 series large current time lag chip fuse are ceramic tube/end cap constructions, RoHS

compliant, Halogen Free and lead(Pb) exempts of the requirements of RoHS Directive(2002/95/EC), with U.S.

(UL/CSA) safety agency approvals. Provide board level primary and secondary circuit protection in a wide variety of applications. With excellent inrush current withstanding capability, excellent reliability for thermal and mechanic shock, also have a high reliability and stable solder ability, end caps are available in gold/silver/nickel plated. Small size, rapid fusing, SMT fitness, is a current protection device designed for high-power industrial application. The device is widely applicable to module power supply, server, energy storage management system and other application environments.

Feature

• Time-Lag (Slow-Blow)

• Small size(10.2mm*3.2mm)

• Wide operating temperature range

• RoHS compliant

• Wide range of current rating available

• Low temperature de-rating

• Tape and Reel for automatic placement

• Conflict free metals

Application

• LED lighting

• Notebook PC

• Portable Devices

• Battery devices

• LCD/PDP devices

• Networking devices

• Telecom system

• LCD backlight inverter

• PC server

• Power supply

• Cooling fan system

• White goods

• Storage system

• Game console

• Medical equipment

• Wireless base station

• Digital camera

• Office equipment

• Automotive devices

• Storage system power

• Cooling fan system for PC server

• Voltage regulator module

• Base station power supply

• Voltage regulator module for PC server

• High end servers / Blade computing

• Battery Management System

Specification

![]()

*: These catalog no. cold resistance and I2t value are pending due to fuse elements shall be customized;

DC Cold Resistance are measured at <10% of rated current in ambient temperature of 25℃;

Typical Pre-arching I2t are calculated at 10*In Current or 8ms;

Min Interrupting Rating: 1.35*In.

Dimension

![]()

Material Details

| NO. | Part number | Material |

| 1 | End cap | Au Plated Brass Cap |

| 2 | Body | Non-Transparent Square Ceramic Tube |

| 3 | Fuse element | Cu-Ag Alloy wire |

Operating Characteristics

| % of Ampere Rating(In) | Blowing Time |

| 100% * In | 4 hours Min |

| 200% * In | 120 sec Max |

Product Characteristics

| NO. | Item | Content | Standard |

| 1 |

Product Marking |

Brand, Ampere Rating |

Marking standards |

| 2 |

Operating Temperature |

-55°C to 125°C |

IEC60068-2-1/2 |

| 3 |

Solderability |

T=240°C±5°C , t=3sec±0.5sec, Coverage≥95% |

IEC60068-2-1/2 |

| 4 |

Resistance to Soldering Heat |

T=240°C±5°C , t=3sec±0.5sec, Coverage≥95% |

MIL-STD-202, Method 208 |

| 5 |

Insulation Resistance (after Opening) |

10,000 ohms minimum |

MIL-STD-202, Method 302, Test Condition A |

| 6 |

Thermal Shock |

5 cycles, -65°C / +125°C, 15 minutes at each extreme |

MIL-STD-202, Method 107, Test Condition B |

| 7 |

Mechanical Shock |

100G’s peak for 6 milliseconds, 3cycles |

MIL-STD-202, Method 213, Test I |

| 8 |

Vibration |

0.03”amplitude, 10-55 Hz in 1 min. 2hrs each XYZ=6hrs |

MIL-STD-202, Method 201 |

| 9 |

Moisture Resistance |

10 cycles |

MIL-STD-202, Method 106 |

| 10 |

Salt Spray |

5% salt solution, 48hrs |

MIL-STD-202, Method 101, Test Condition B |