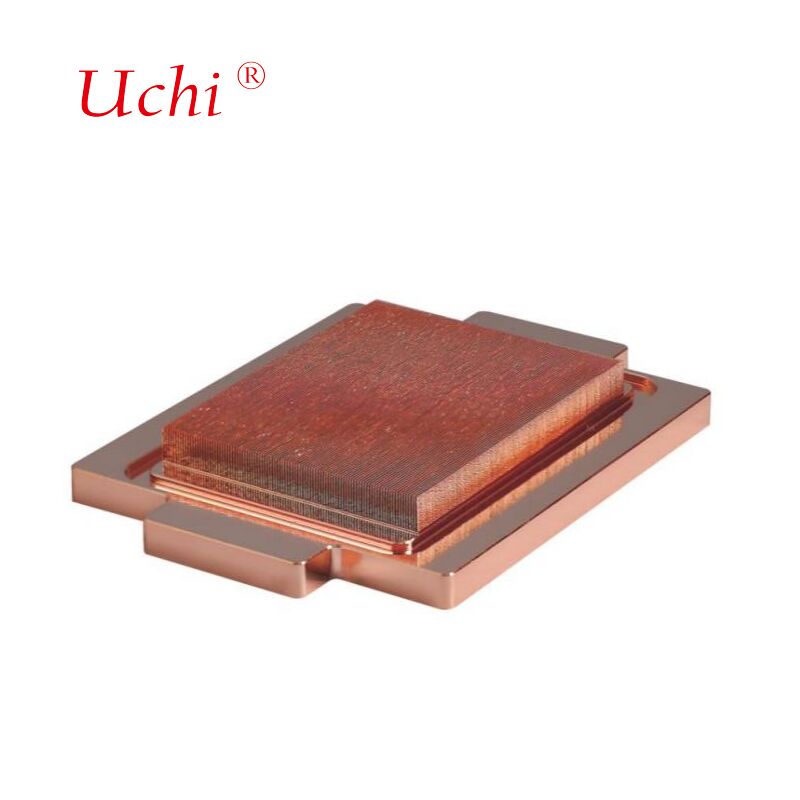

Cold Plate Heat Sink For CPU Microprocessor Electronic Devices

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | skived fin heat sink 02 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Processing Service: | Cutting, Punching, Decoiling, Bending, Drilling | Temper: | T3~T8 |

|---|---|---|---|

| Packing: | PE Bag Carton | Tolerance: | ±1% |

| Standard: | Middle And High Quality Aluminium Heatsink | Deep Process: | CNC Machining |

| Material: | Copper, Aluminum | Technology: | CNC & Skiving |

| Highlight: | CPU cold plate heat sink,microprocessor liquid cooling plate,electronic devices heat sink |

||

Product Description

Cold Plate Heat Sink for CPU Microprocessor Electronic Devices

Advanced liquid cooling solutions for high-performance computing applications including AI, data centers, and electronic devices requiring superior thermal management.

Manufacturing Specifications

| Business Type | Factory / Manufacturer |

|---|---|

| Products | Skiving Fin Heatsinks, Liquid Cold Plates, Extruded Heatsinks, Stamping Heatsinks, Heat Pipe Heatsinks, Vapor Chamber, CNC Machined Parts |

| Type | Heatsinks |

| Service | OEM service, professional R&D support |

| Material | Aluminum/copper |

| Tool Cost | No Needed |

| Process | Cutting, Skiving, Extruded, Stamping, Rolling, Broaching, Punching, Drilling, Bending, Welding, Milling, Turning, CNC Machining, Grinding, Deburring, Cleaning, 100% Inspection, Packing, Delivery |

| Surface Treatment | Polishing, anodizing, powder coating, passivating, painting, plating, sand blasting, e-coating and others as requested |

| Dimension | Customized (Maximum skived heat sink size: W 1200 × L 3500mm) |

| Inspection | CMM, Two dimensional measuring instrument, Projector, Flatness measurer, Roughness measurer, Helium leaking testing equipment |

| Delivery Time | Sample lead time: 15-21 days. Production lead time: 25 days. |

Industry Applications

Photovoltaics, Wind Power, Communications, LED, Electric Vehicles, Medical, Rail Transit, Microwaves, Automobile, Lasers, High Power Solar Inverter, High Power LED light, Data Center, IGBT cooling, Welding Machine, Artificial Intelligence

Advanced Cooling Solutions for Next-Generation Processors

With the rise of AI and HPC processing massive data volumes, next-generation processors will generate significantly more heat than current high-end models. BY Thermal's liquid cooling solutions maximize heat dissipation efficiency, improve PUE values, and increase computing density per rack, positioning liquid cooling as essential for future data center infrastructure.

High-End Manufacturing Applications

Semiconductor and Chip Manufacturing: Advanced packaging technologies like 3D stacking create internal heat accumulation where traditional material thermal conductivity becomes a bottleneck.

AI Computing/Data Centers: Surging chip heat flux density challenges traditional cooling methods, making thermal management a critical factor in computing power improvement.

Aerospace: Extreme temperature environments and vacuum conditions eliminate convective heat dissipation options, requiring specialized thermal management solutions.

Everyday Applications

Digital Devices: Metal cooling fins in computers, mobile phones, and game consoles ensure sustained performance.

Communication Devices: Large heat sinks maintain stability for high-speed data transmission and processing.

Household Appliances: Compressors and condensers require efficient heat transfer from indoor to outdoor environments.

Lighting Devices: Efficient heat dissipation ensures LED luminous efficacy and extended service life.

New Energy Vehicles: Sophisticated liquid cooling systems maintain optimal operating temperatures.

Manufacturing Capabilities

Our mold workshop features 22 electric discharge machines including 2 MAKINO mirror EDM machines, 9 wire-cut EDM machines (3 Seibu and 1 Sodick from Japan), 7 spark erosion machines, 10 grinding machines, 2 milling machines, and 1 lathe.

Technical Specifications

- Table size: 500×350 mm

- Rapid traverse speed: 5000 mm/min

- Maximum workpiece weight: 500 kg

- Maximum electrode weight: 50 kg

Precision Engineering

Utilizing SuperSpark4 and IES (Intelligent Expert System) technologies for adaptive power supply and jump control to stabilize EDM processes and enhance machining precision. Advanced ultra-surface and ultra-edge generator technologies deliver exceptional surface finish and metallurgical quality.

Product Applications

Quality Assurance

Rigorous quality standards maintained with comprehensive testing equipment:

- 1 Coordinate Measuring Machine

- 1 projector instrument

- 2 water high pressure testing machines

- 4 thermal resistance testing machines

- 2 liquid leakage testing machines

Customer Service Commitment

- Prompt response to all inquiries

- Competitive pricing with guaranteed quality

- Efficient production scheduling

- Optimal transportation solutions

- Comprehensive technical support

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a professional manufacturer of heat sinks and water cooling plates with extensive experience and a strong technical team, featuring automated and mechanized production.

Have you exported goods before and to which regions?

60% of our total production is exported to Japan, India, UK, Canada, USA, and Brazil.

How many employees do you have?

Approximately 100 employees across sales, purchasing, engineering, QA, warehouse, and production departments.

Can you provide samples if we agree with the design?

Yes, we provide samples for confirmation before mass production, along with technical drawings if required.

What packing methods do you use?

Customized packing with normal cartons and tight-proof fabric or wooden cartons for optimal protection during transportation.

Do you provide technical support for product issues?

All products are fully inspected before shipping. For any issues, we provide immediate technical solutions.

Want to Know more details about this product