Mini High Dense Aluminum Skiving Heat Sink For LED

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | Heat Sink |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Heat Conducting Power: | 20W | Fan Life: | 50000 Hrs |

|---|---|---|---|

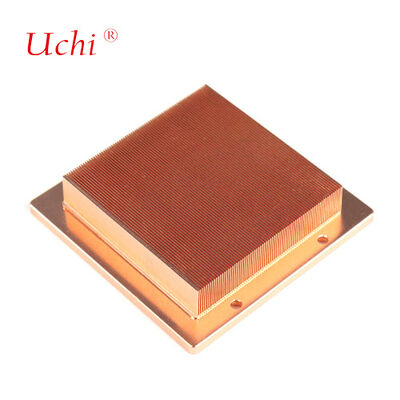

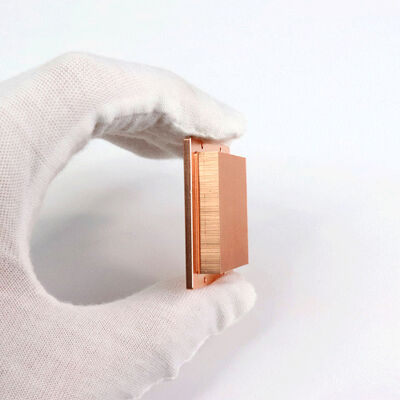

| Material: | Copper 1020 | Size: | 37x37x7mm |

| Weight: | 0.035 Kg | Technology: | Skiving + Passivation |

| Certification: | ISO9001:2015 ISO9001:14001 | Surface Treatment: | Passivation |

| Feature: | Reliable Performance And Durable In Surface Treatment | ||

| Highlight: | mini aluminum LED heat sink,high dense skiving heat sink,aluminum heat sink for LED |

||

Product Description

Mini High Dense Aluminum Skiving Heat Sink For LED

Mini High Dense Aluminum Skiving Heat Sink designed specifically for LED applications, featuring reliable performance and durable surface treatment.

Product Specifications

Material:

Copper 1020

Dimensions:

37×37×7mm

Weight:

0.035 kg

Heat Conducting Power:

20W

Surface Treatment:

Passivation

Product Technology:

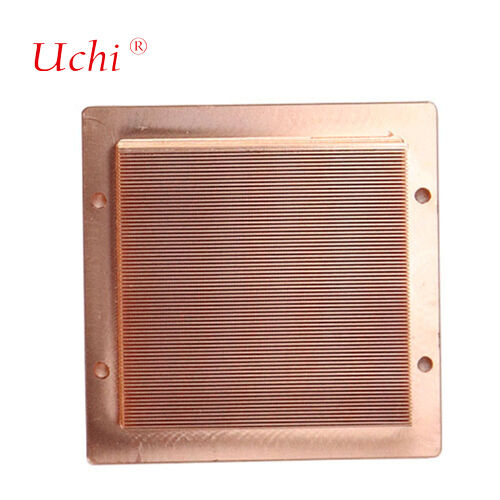

Skiving + Passivation

Technology Overview

Skiving fin technology involves relieving aluminum teeth to create specific profiles such as radiators using specialized skiving fin machine tools. The resulting skiving fin heat sink features a gap structure with the same sequence formed by cutting material at specific angles through mechanical action of strip profiles (aluminum and copper).

This technology effectively solves heat dissipation challenges for high-power devices under air cooling conditions, increasing heat dissipation efficiency by 8-15% compared to other heat sink types.

Primary Application Fields

- 100G/200G pluggable optical modules for data center switches

- Small optical modules for fronthaul/mid-haul equipment of 5G base stations

- Low-power optical communication components for edge computing nodes

- UPS, base stations, charging piles, frequency converters

- Controllers, wind power converters, SVG, LED lamps

Manufacturing Capabilities

Advanced Brazing Technology

Brass / Copper CNC

Aluminium / Zinc CNC

Stainless Steel / Steel CNC

Plastic CNC

Key Applications

| Industry | Applications |

|---|---|

| New Energy Vehicles | Thermal management of battery packs, motor controllers, inverters |

| Industrial Electronics | Inverters, IGBT modules, high-power semiconductor devices, laser equipment |

| Data Center and Server | Cooling of high-performance computing components (CPU, GPU, memory) |

| Medical Devices | Temperature control of imaging equipment and diagnostic instruments |

| Aerospace and Military | Airborne equipment and radar systems requiring high reliability |

| Power Electronics | Rectifiers, transformers, and power modules |

| Renewable Energy | Photovoltaic inverters, wind turbine converters |

| LED Lighting | Heat dissipation of high-power LED lamps |

Production Equipment

Our manufacturing facility features comprehensive air-cooled equipment including:

- 10 low-temperature solder reflow ovens

- 5 baking ovens

- 20 automatic solder dispensing units

- 3 automatic solder brushing machines

- 50 torque-controlled electric screwdrivers

- CCD inspection equipment

- Fully automatic optical module testing systems

- Multi-station thermal performance testing equipment

- Flatness optical testing instruments

Quality Assurance

We maintain rigorous quality standards with advanced testing equipment including Coordinate Measuring Machines, projector instruments, water high pressure testing machines, thermal resistance testing systems, and liquid leakage testing equipment.

Customer Service

- Prompt response to all inquiries

- Competitive pricing with guaranteed quality

- Efficient production scheduling

- Optimal transportation solutions

- Comprehensive technical support

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a professional manufacturer of heat sinks and water cooling plates with extensive experience and a strong technical team, featuring automated and mechanized production.

Have you exported goods before and to which regions?

60% of our total production is exported to Japan, India, UK, Canada, USA, and Brazil.

How many employees do you have?

Approximately 100 employees across sales, purchasing, engineering, QA, warehouse, and production departments.

Can you provide samples if we agree with the design?

Yes, we provide samples for confirmation before mass production, along with technical drawings if required.

What packing methods do you use?

Customized packing with normal cartons and tight-proof fabric or wooden cartons for optimal protection during transportation.

Do you provide technical support for product issues?

All products are fully inspected before shipping. For any issues, we provide immediate technical solutions.

Want to Know more details about this product