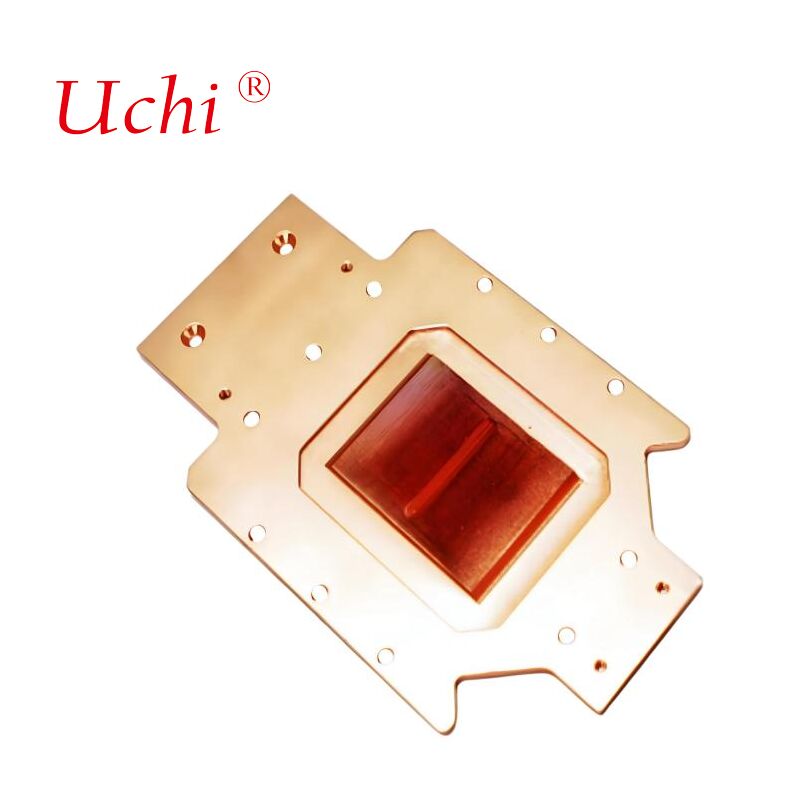

Custom Cold Plates Of CNC Machined Anodized Heat Sink Copper Cold Plate

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | custom cold plates |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Power Interface: | 3Pin | Material: | Copper |

|---|---|---|---|

| Noise: | 17dbA | Power: | 20-500W |

| Surface Treatment: | Color Anodize | Process: | Brazed Skived Fin |

| Certificate: | ISO 9001:2000 ISO 14001:2004 | Tolerance: | 0.01-0.05mm |

| Highlight: | CNC machined copper cold plate,anodized heat sink cold plate,custom liquid cooling plate |

||

Product Description

Custom CNC Machined Anodized Copper Cold Plates

Heat dissipation plays a pivotal role in digital economy development. As the physical cornerstone of digital infrastructure and essential component in the computing power industry chain, thermal management technology supports various digital applications—from national data centers and AI computing clusters to personal computers, smartphones, and IoT devices—ensuring robust operation and sustained growth of the digital economy.

Industrial Applications

High-end Manufacturing Applications

- Semiconductor and Chip Manufacturing: Advanced packaging technologies like 3D stacking create internal heat accumulation where traditional material thermal conductivity becomes a bottleneck

- AI Computing/Data Centers: With increasing chip heat flux density, traditional cooling methods struggle to meet demands, making thermal management a critical factor in computing power improvement

- Aerospace: Extreme space environments with temperature fluctuations and high vacuum conditions where convective heat dissipation is not feasible

Consumer Applications

- Digital Devices: Internal heat dissipation modules with metal cooling fins in computers, mobile phones, and game consoles ensure sustained performance

- Communication Devices: Large heat sinks maintain stability for high-speed data transmission and processing

- Household Appliances: Compressors and condensers require efficient heat dissipation to transfer heat from indoor spaces outdoors

- Lighting Devices: Efficient heat dissipation design ensures LED lamp bead efficacy and longevity while supporting energy conservation

- New Energy Vehicles: Sophisticated liquid cooling systems maintain optimal operating temperatures

Industry Challenges

Traditional heat dissipation manufacturing faces significant challenges:

- Traditional air-cooling technology cannot meet the 50W/cm²+ heat flux density demands of high-performance AI processors

- Thermal conductive materials have reached performance bottlenecks with conventional thermal greases struggling to exceed 5W/m*K thermal conductivity

- Liquid cooling technology offers superior performance but involves complex production processes and high technical requirements

Industry Transformation

The heat dissipation industry is undergoing strategic transformation from supporting role to core technology sector with clear upgrading paths:

- Technology: Shifting from uniform heat dissipation to precision temperature control with liquid cooling as mainstream solution

- Industrial Positioning: Transforming from manufacturer to "heat dissipation as a service" solution provider

- Material Systems: Evolving toward high thermal conductivity and intelligent materials

- Manufacturing Paradigms: Deep integration of digitalization and additive manufacturing

This transformation represents an identity revolution from auxiliary process to leading design, with heat dissipation capacity becoming a core indicator of digital economy competitiveness.

Cold Plate Radiator Design

We provide custom internal flow channel design based on customer power consumption data and heat distribution patterns. Our engineering process includes comprehensive simulation analysis with iterative parameter adjustments to achieve optimal thermal and hydraulic performance targets.

Manufacturing Capabilities

Advanced Equipment Infrastructure

Our mold workshop features comprehensive manufacturing capabilities:

- 22 electric discharge machines (EDM) including 2 MAKINO mirror EDM machines

- 9 wire-cut EDM machines (low-speed) with 3 Seibu and 1 Sodick imported from Japan

- 7 spark erosion machines, 10 grinding machines, 2 milling machines, and 1 lathe

Technical Specifications

| Parameter | Specification |

|---|---|

| Table Size | 500×350 mm |

| Rapid Traverse Speed | 5000 mm/min |

| Maximum Workpiece Weight | 500 kg |

| Maximum Electrode Weight | 50 kg |

Precision Machining

Utilizing SuperSpark4 and IES (Intelligent Expert System) technologies, we provide advanced adaptive power supply and jump control to stabilize EDM processes and improve machining precision. Equipped with ultra-surface and ultra-edge generator technologies, we achieve excellent surface finish and metallurgical quality.

Liquid Cooling System Technology

High-power liquid cooling systems require heat sinks capable of rapid heat absorption. Leveraging the high specific heat capacity of liquids, our systems transfer large amounts of heat through liquid flow, capable of dissipating heat ranging from several hundred watts to over one kilowatt.

Liquid Cold Plate Varieties

- Buried-tube Liquid Cold Plate: Fabricated by grooving plates, burying and welding copper tubes inside, then hermetically sealing via welding. Ensures reliable liquid tightness, operational safety, and high flatness for excellent thermal contact.

- Inserted-tube Liquid Cold Plate: Manufactured by embedding copper tubes onto aluminum plate surfaces using welding or bonding processes, with strict flatness control for minimal thermal resistance.

- Channel-type Liquid Cold Plate: Internal flow channels formed on copper or aluminum substrates through drilling, extrusion, and precision machining, sealed via friction welding or high-temperature brazing.

- Liquid Cooling Block: For high-power chip heat dissipation with internal flow channels created through skiving fin technology to maximize heat exchange surface area.

Quality Assurance

We maintain rigorous quality standards with comprehensive testing equipment including:

- 1 Coordinate Measuring Machine

- 1 projector instrument

- 2 water high pressure testing machines

- 4 thermal resistance testing machines

- 2 liquid leakage testing machines

Customer Service Commitment

- Prompt response to all inquiries

- Competitive pricing with guaranteed quality

- Efficient production scheduling

- Optimal transportation solutions

- Comprehensive technical support

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a professional manufacturer of heat sinks and water cooling plates with extensive experience and a strong technical team, featuring automated and mechanized production.

Have you exported goods before and to which regions?

60% of our total production is exported to Japan, India, UK, Canada, USA, and Brazil.

How many employees do you have?

Approximately 100 employees across sales, purchasing, engineering, QA, warehouse, and production departments.

Can you provide samples if we agree with the design?

Yes, we provide samples for confirmation before mass production, along with technical drawings if required.

What packing methods do you use?

Customized packing with normal cartons and tight-proof fabric or wooden cartons for optimal protection during transportation.

Do you provide technical support for product issues?

All products are fully inspected before shipping. For any issues, we provide immediate technical solutions.

Want to Know more details about this product