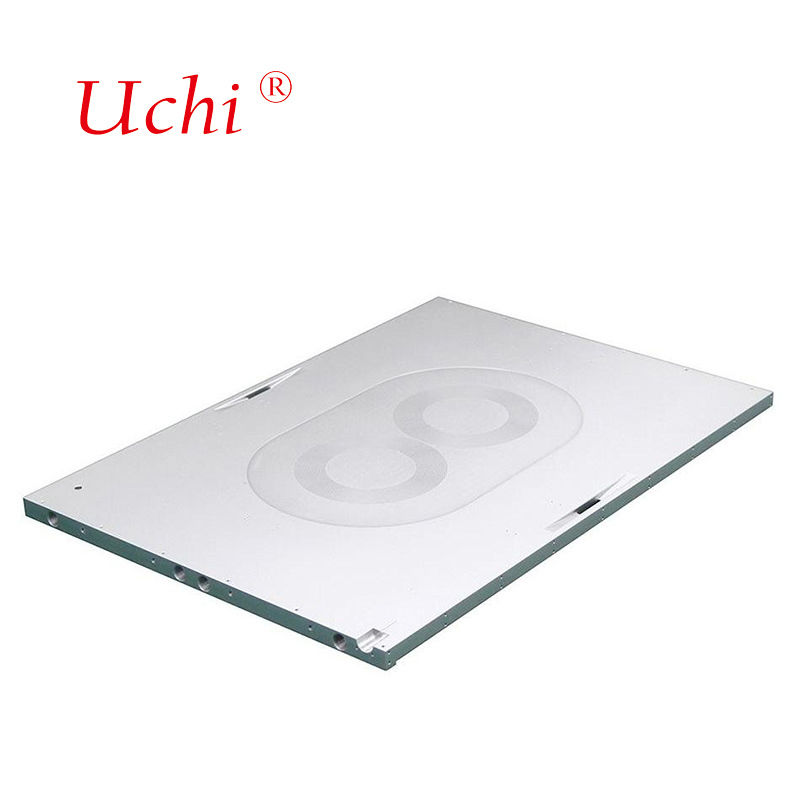

Laser Fiber Friction Stir Welding Of Water-cooled Plates ,Hydronic Cooling Plate

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | Cooling plate 63 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Material: | Aluminum Alloy | Working Pressure: | At Least 1 Bar |

|---|---|---|---|

| Surface Finish: | Mill Finish Or Anodization | Single Package Size: | 45X40X10 Cm |

| Single Gross Weight: | 5.000 Kg | Warranty: | 1 Year |

| Highlight: | water-cooled laser fiber welding plate,hydronic cooling friction stir plate,liquid cooling plate with water-cooled design |

||

Product Description

Laser Fiber Friction Stir Welded Water-Cooled Plates

Hydronic Cooling Plate for High-Power Applications

Our laser fiber friction stir welded water-cooled plates are constructed from AL6063 aluminum alloy. The manufacturing process involves deep hole drilling to create longitudinal channels, followed by milling at transverse intervals. These channels are then securely joined using friction stir welding technology. This advanced method provides superior compressive strength and thinner profiles, making it ideal for high-power fiber optic equipment cooling applications. The result is significantly enhanced heat dissipation performance that meets diverse thermal management requirements.

Product Specifications

| Process | Friction welding | Hardness | T3-T8 |

|---|---|---|---|

| Material | AL6063 | Shape | Square |

| Application | High-power laser equipment | Certificates | ISO 9001:2015, ISO 14001:2015 |

| Model | LR0192 | Tolerance | 0.01 mm |

| Surface treatment | Passivation | Quality inspection | Full inspection |

| Additional process | CNC machining | Size | Customizable |

Manufacturing Processes

Vacuum Brazing Furnace

CNC Machining

Aluminum Extrusion

Skiving production line

Die casting production line

Aluminum Extrusion

Applications

- Lasers

- Medical equipment

- EV power battery pack cooling

- Power electronics

- Motor drive devices

- Microwave 5G transmission

- Renewable energy systems

- IGBT and Power Semi-Conductor Systems

- Data Centers

- Industrial Power Applications

- Defense Systems

- Avionics

- Fuel Cells

- Traction Systems

Detailed view of cooling plate water channels

Production Capabilities

25 CNC machines, 10 stamping machines, 2 friction welding machines, 2 large thermal blowers, 4 wire cutting machines, 2 spark machines, 4 milling machines and 3 grinding machines.

Quality Assurance

1 Coordinate Measuring Machine, 1 projector instrument, 2 water high pressure testing machines, 4 thermal resistance testing machines, and 2 liquid leakage testing machines.

Customer Service

- Prompt response to all inquiries

- Competitive pricing with guaranteed quality

- Efficient production scheduling

- Optimal transportation solutions

- Comprehensive technical support

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a professional manufacturer of heat sinks and water cooling plates with extensive experience and a strong technical team, featuring automated and mechanized production.

Have you exported goods before and to which regions?

60% of our total production is exported to Japan, India, UK, Canada, USA, and Brazil.

How many employees do you have?

Approximately 100 employees across sales, purchasing, engineering, QA, warehouse, and production departments.

Can you provide samples if we agree with the design?

Yes, we provide samples for confirmation before mass production, along with technical drawings if required.

What packing methods do you use?

Customized packing with normal cartons and tight-proof fabric or wooden cartons for optimal protection during transportation.

Do you provide technical support for product issues?

All products are fully inspected before shipping. For any issues, we provide immediate technical solutions.

Want to Know more details about this product