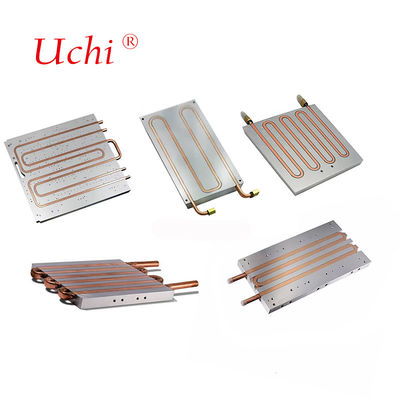

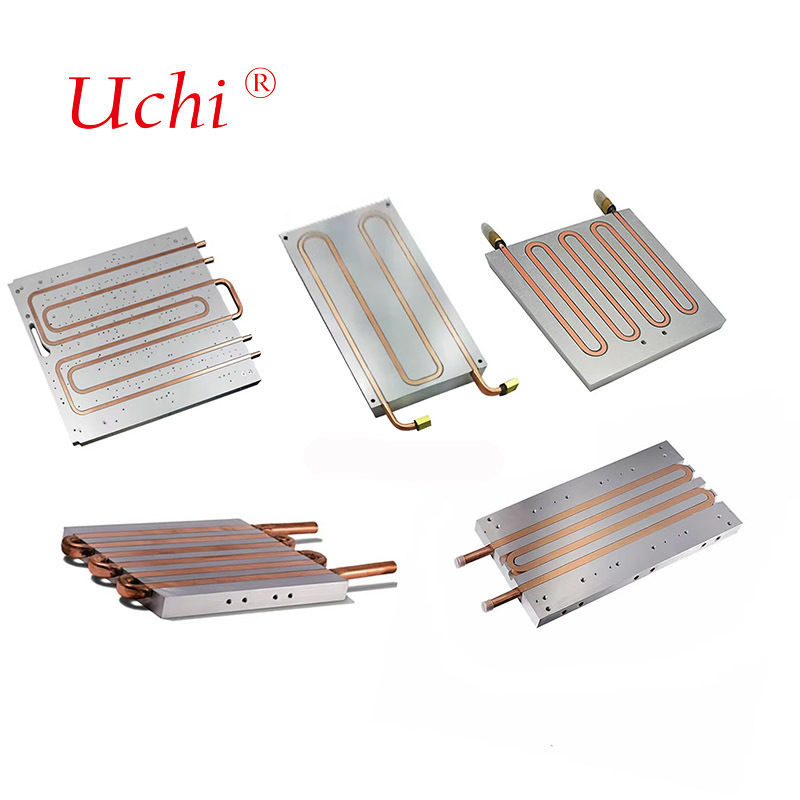

Customized Liquid Cooling Plate Copper-Aluminum Heat Sink Water Cooling Plate Cold Plate Cooling System

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | cold plate cooling system-09 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union, MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Product Weight: | 2.323 Kg | Type: | Refrigeration Compressor ,Evaporator ,Cooler , Heat... |

|---|---|---|---|

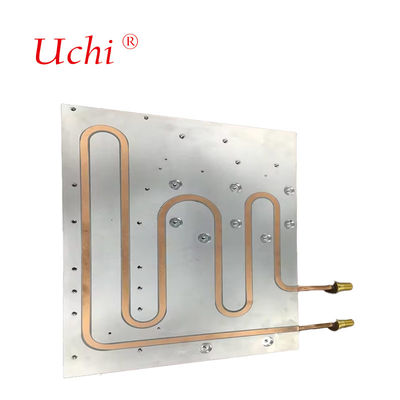

| Treatment: | Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating And Laser Marking | Bonding Technology: | FSW, Pressure Pipe |

| Material: | Aluminum,Aluminum+Cooper Tube | Size: | 32X22X1.2cm |

| Highlight: | copper-aluminum liquid cooling plate,custom water cooling plate,cold plate heat sink system |

||

Product Description

Customized Liquid Cooling Plate Copper-Aluminum Heat Sink Water Cooling Plate Cold Plate Cooling System

Custom Cold Plates for Mission Critical Power Electronics Cooling. The drive towards higher power and more compact packages is making liquid cooling a necessity in many applications. Partnering with Original Equipment Manufacturers (OEMs), we supply custom cold plates for electronics cooling and other applications where high performance and high reliability are essential.

Friction Stir Welding Advantages

- High welding quality: Solid-state connection method prevents common defects like pores and hot cracks, ensuring sealing and reliability.

- High weld strength: Joint strength reaches over 95% of base material, withstanding considerable pressure and tensile force.

- Minimal thermal deformation: Low temperature process maintains dimensional accuracy for precision applications.

- Design flexibility: Enables complex shapes and fine flow channel structures for optimized thermal performance.

- Environmental benefits: No filler materials or protective gases required, reducing waste and energy consumption.

- Production efficiency: Simple process with fast welding speeds suitable for mass production.

- Material compatibility: Works with aluminum and copper alloys, including connections between different materials.

Manufacturing Process

Each heat sink undergoes multiple processes including drawing design, CNC machining, friction stir welding, soldering, assembly, skiving/extrusion, testing, and surface treatment.

Product Applications

This coolant plate is suitable for cooling computer CPUs, GPUs, motherboards, Xbox consoles, semiconductor cooling sheets, industrial drives, laser heads, and industrial control cabinets.

Key Features

- Aluminum alloy material - lightweight, rust-proof and durable

- Compatible with water pipes (7-8mm inner diameter)

- Polished surface with extruded/machined M-shaped flow channels

- High performance with excellent thermal uniformity

- Compact design compatible with various coolants

Packaging

All heat sinks and cooling plates are packed in EPE foam and cartons with wooden frame protection. Larger items may use wooden boxes with thick EPE padding for maximum protection during shipping.

Our Service Commitment

- Prompt response to all inquiries

- High quality products at competitive prices

- Efficient production scheduling for on-time delivery

- Optimal transportation solutions based on product specifications

- Comprehensive technical support and problem resolution

Want to Know more details about this product