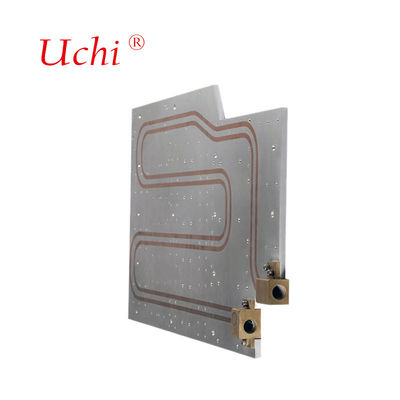

Custom Cold Plates FSW Water-Cooled Plate Or Epoxy-Filled Water-Cooled Plate

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | custom cold plates-10 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union, MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Material: | Aluminum,Aluminum+Cooper Tube | Process: | CNC, Buried Pipe, Brazing |

|---|---|---|---|

| Inspection: | Calipers,CMM | Type: | 100% QC Testing |

| Shape: | Custom | Size: | Customizable |

| Surface Treatment: | Anti-oxidation Coating, Nickel Plating | Service: | OEM ODM Custom Service |

| Highlight: | custom FSW water-cooled plate,epoxy-filled liquid cooling plate,cold plate for liquid cooling |

||

Product Description

In compact designs where power density is increasing, our cold plates meet demanding contact cooling requirements for applications including:

- High-power electronics

- Power generation systems

- Medical equipment

- Military and aerospace applications

- Laser systems

When air-cooled heat sinks are insufficient for high watt density applications, our liquid-cooled cold plates provide ideal high-performance heat transfer solutions.

Uchi offers three distinct cold plate technologies with complete custom design and manufacturing capabilities, plus over 15 standard product lines to address your thermal challenges.

Our customized cold plates cool mission-critical power electronic devices where higher power and compact packaging make liquid cooling essential. We collaborate with OEMs to deliver solutions where high performance and reliability are critical.

Our cold plate technologies include:

- Vacuum brazed cold plates

- Friction stir welded (FSW) performance finned cold plates and chassis

- Flat tube cold plates

- Tubular cold plates

Each heat sink product undergoes multiple processes:

- Drawing design

- CNC machining

- Friction stir welding

- Soldering

- Assembly

- Skiving and extrusion

- Testing

- Surface treatment

Our heat sinks and water cold plates serve diverse industries including:

- Transportation systems

- CPU computers and servers

- LED lighting

- Laser equipment

- Air conditioning systems

- All electrical products generating heat

All products are securely packaged to ensure safe delivery:

- EPE foam cushioning inside cartons

- Wooden frame reinforcement for cartons

- Waterproof packaging transparent film

- Larger items use wooden cartons with thick EPE protection

A: We are professional heat sink and water cooling plate manufacturers with extensive experience and a strong technical team, featuring automated and mechanized production.

A: 60% of our total production is exported worldwide, including Japan, India, UK, Canada, USA, and Brazil.

A: Our team consists of approximately 100 employees across sales, purchasing, engineering, QA, warehouse, and production departments.

A: Yes, we provide samples for confirmation before mass production and can supply technical drawings when needed.

A: We use customized packaging with either standard cartons reinforced with protective fabric or wooden cartons for optimal protection during transportation.

A: All products undergo thorough inspection before shipping. For any issues, we provide immediate technical support and solutions.