Customized Water Cooling Plate for IGBT Modules

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | Cold Plate-16 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union, MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Material: | Copper Product | Treatment: | Passivation Heat Conducting |

|---|---|---|---|

| Product Technology: | CNC Machine + Surface Finish | Type: | Aluminum Profile |

| Article No: | Liquid Cooling Plate 14 | Texture Of Material: | 6061 |

| Highlight: | IGBT Modules Liquid Cooling Plates,SMC Compliant Water Cold Plates,Water Cooling Plate OEM |

||

Product Description

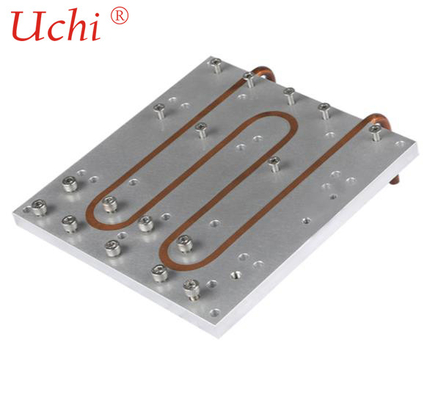

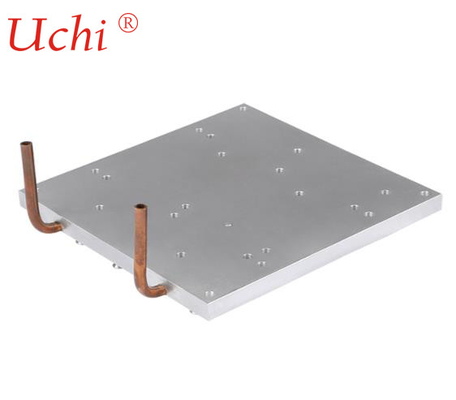

Water Cooling Plate for IGBT Modules

Liquid cold plate uses a pump to circulate the coolant in the heat pipe and dissipate heat. The heat absorption part on the radiator (called the heat absorption box in the liquid cooling system) is used to dissipate heat from the computer CPU, North Bridge, graphics card, lithium battery, 5G communication equipment, UPS and energy storage system, and large photovoltaic inverter , SVG/SVC absorbs heat on heat dissipation. The heat absorbed by the heat absorption part is discharged to the outside through the radiator designed on the back of the pyrogen.

In the fields of power electronic control, conversion, drive, signal transmission, and new energy fields (new energy vehicle power battery heat dissipation, UPS and energy storage system heat dissipation, large server heat dissipation, large photovoltaic inverter heat dissipation, SVG/SVC heat dissipation, etc.), In order to pursue high-efficiency, low-noise and low-temperature operation, and when space is limited, heat dissipation becomes the biggest limit to the idealization of product development, and liquid cooling technology has become the preferred thermal management method.

Winshare's thermal design and thermal management engineers have rich experience in water cooling system research and development and water cold plate process production, and can provide a full range of liquid cooling solutions, and provide you with liquid cooling plate/water cooling plate thermal design, structural design, and water channels for free Connected water cooling system assembly design and one-stop supporting services.

Product designing and manufacturing of New product optical fiber water cold plate double fiber laser equipment water cold plate

![]()

Every products of heat sinks needs several process including the drawing design, CNC machining, friction welding stir, soldering, assembly, skiving and extrusion, Testing and finally turn to the step in the surface treatment.

Product application of New product optical fiber water cold plate double fiber laser equipment water cold plate

![]()

![]()

Our heat sinks and water cold plates has been utilized in many of fields, including transportation, CPU computer, servers, Led light, Laser equipment and air condition and so on as long as any electrical product that generate the heat.

So when you are designing the thermal heat sinks or any radiators, there must be some of them may be met your requirement.

Packing details of New product optical fiber water cold plate double fiber laser equipment water cold plate

![]()

All the heat sinks, water cold plates and heat pipes are packed in the EPE foam and in the carton, the carton itself has the strong protection using the wooden frame for it and finally utilize the Packaging transparent film as it is water proof, some of the larger heat sinks or water cooling plate may adopt the wooden carton due to the special demanding, wooden box inside has the thick EPE that offer great protection from inside and outside knocking!

Our service

1.Once received the inquiry will be quickly replied

2.Keep the product be qualified and price be reasonable and competitive.

3.Fastly arrange production and improve efficiency. Get the goods be finished on time.

4.We can advice the best transportation depends on the goods weight and cubic meter

5.Any questions with the goods we made, we will offer the best solution and technique support.

FAQ

1. Q:Are you trading in company or manufacturer?

A:We are the professional manufacturer of heat sink and water cooling plate

that has much experiences and strong technique team, automatically and mechanized production

2. Q:Have you exported the goods before and to which regions?

A:60% goods in total has exported abroad, to Japan, India ,British, Canada, America and Brazil.

3. Q:How many employees you have?

A:we have about 100 employees ,including sales, purchase ,engineering ,QA ,warehouse and production department.

4. Q:If I agree with the design, can you provide the samples we need?

A:Yes,we can we surely will provide the samples to you for confirmation before mass production. Meanwhile the drawing we could provide if needed

5. Q:What packing you're using and can be assured safety?

A:Every goods are be packed with customized packing ways in normal cartons with tight proof fabric and wooden cartons for great protection,

so it is safe during transportation.

6. Q:If we have any questions with products, can you provide the technique and solution?

A:Every products are fully checked before shipping, if there is problems you're facing, please feel free to let us know, we will offer best solution at once.