1-50 Kg Single Point Weighing Sensor Strain Gauge Czl635 For Kitchen Scales

Product Details:

| Place of Origin: | GUANGDONG,CHINA |

| Brand Name: | UCHI |

| Certification: | SGS,ROHS. |

| Model Number: | CZL635 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 10 Workdays |

| Payment Terms: | Western Union, MoneyGram, T/T |

| Supply Ability: | 500000pcs/month |

|

Detail Information |

|||

| Product: | Weighing Sensor | Rated Load: | 1-50KG |

|---|---|---|---|

| Comprehensive Error (%FS): | 0.05 | Rated Output (mV/V): | 0.7±0.15 |

| Dimensions (mm): | 55×12.7×12.7 | MOQ: | 500PCS |

| Highlight: | thermocouple temperature sensor,high precision temperature sensor |

||

Product Description

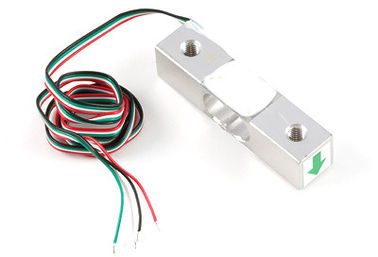

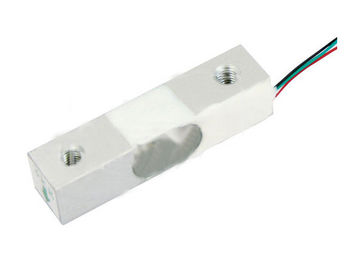

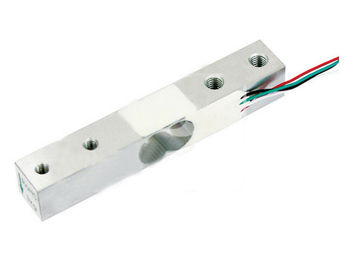

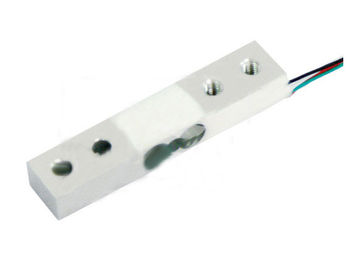

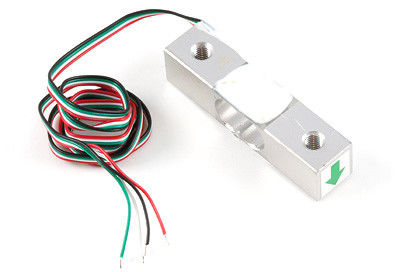

1-50 Kg Single Point Weighing Sensor Strain Gauge Czl635 For Kitchen Scales

Introduction

A load cell is a force sensing module - a carefully designed metal structure, with small elements called strain gauges mounted in precise locations on the structure. Load cells are designed to measure a specific force, and ignore other forces being applied. The electrical signal output by the load cell is very small and requires specialized amplification. Fortunately, the 1046 PhidgetBridge will perform all the amplification and measurement of the electrical output.

Load cells are designed to measure force in one direction. They will often measure force in other directions, but the sensor sensitivity will be different, since parts of the load cell operating under compression are now in tension, and vice versa.

This Single Point Load Cell is used in small jewelry scales and kitchen scales. It’s mounted by bolting down the end of the load cell where the wires are attached, and applying force on the other end in the direction of the arrow. Where the force is applied is not critical, as this load cell measures a shearing effect on the beam, not the bending of the beam. If you mount a small platform on the load cell, as would be done in a small scale, this load cell provides accurate readings regardless of the position of the load on the platform.

Dimensional drawing

![]()

Product specifications

Sensor Properties

| Sensor Type | Shear Load Cell |

| Weight Capacity Max | 5 kg |

| Maximum Overload | 6 kg |

| Creep | 5 g/hr |

| Zero Balance | ± 75 g |

| Cell Repeatability Error Max | ± 2.5 g |

| Cell Non-Linearity Max | 2.5 g |

| Cell Hysteresis Max | 2.5 g |

| Temperature Effect on Span | 250 mg/°C |

| Temperature Effect on Zero | 500 mg/°C |

Electrical Properties

| Rated Output | 1 mV/V |

| Rated Output Error Max | ± 150 μV/V |

| Output Impedance | 1 kΩ |

| Supply Voltage Max | 5 V DC |

Physical Properties

| Compensated Temperature Min | -10 °C |

| Compensated Temperature Max | 40 °C |

| Operating Temperature Min | -20 °C |

| Operating Temperature Max | 55 °C |

| Cable Length | 550 mm |

| Cable Gauge | 30 AWG |

| Material | Aluminium Alloy (LY12CZ) |

| Screw Thread Size |

M5x0.8

|

How they work

Strain-gauge load cells convert the load acting on them into electrical signals. The measuring is done with very small resistor patterns called strain gauges - effectively small, flexible circuit boards. The gauges are bonded onto a beam or structural member that deforms when weight is applied, in turn deforming the strain-gauge. As the strain gauge is deformed, it’s electrical resistance changes in proportion to the load.

The changes to the circuit caused by force is much smaller than the changes caused by variation in temperature. Higher quality load cells cancel out the effects of temperature using two techniques. By matching the expansion rate of the strain gauge to the expansion rate of the metal it’s mounted on, undue strain on the gauges can be avoided as the load cell warms up and cools down. The most important method of temperature compensation involves using multiple strain gauges, which all respond to the change in temperature with the same change in resistance. Some load cell designs use gauges which are never subjected to any force, but only serve to counterbalance the temperature effects on the gauges that measuring force. Most designs use 4 strain gauges, some in compression, some under tension, which maximizes the sensitivity of the load cell, and automatically cancels the effect of temperature.

Other types of load cell exist which have half bridges (2 strain gauges) or quarter bridges but they require additional hardware to operate since you must complete the bridge to get the most accurate readings.

What is a Wheatstone bridge?

A Wheatstone bridge is an electrical circuit used to measure and unknown resistance by balancing 2 legs of a bridge circuit. One leg of which contains the unknown value. Wheatstone bridges are made up of 4 resistors or loads in a square with a voltage meter bridging 2 corners of the square and power/ground connected to the other corners. In the case of a load cell, these resistors are strain gauges.

Installation

A single-point load cell. Applying force to one end creates stress in the bar, causing the strain gauge encased in the white plastic to flex.This Single Point Load Cell is used in small jewelry scales and kitchen scales. It’s mounted by bolting down the end of the load cell where the wires are attached, and applying force on the other end in the direction of the arrow. Where the force is applied is not critical, as this load cell measures a shearing effect on the beam, not the bending of the beam. If you mount a small platform on the load cell, as would be done in a small scale, this load cell provides accurate readings regardless of the position of the load on the platform.

Button Load Cells

A button load cell. Applying force to the bump in the middle of the cell causes a change in the output.This Button Load Cell is used in applications that require a thin form factor. The bottom of the load cell is bolted, and force applied to the button on the top. By loading only the button, which is slightly rounded, the load cell is less sensitive to errors resulting from the load not pushing down exactly straight on the load cell.

An S-type load cell. By pulling on both ends or pushing on both ends, the stress in the S changes and the cell's output changes.This S-Type load cell can be operated in compression or tension, as illustrated below.