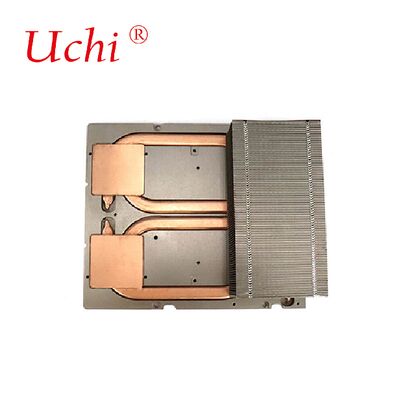

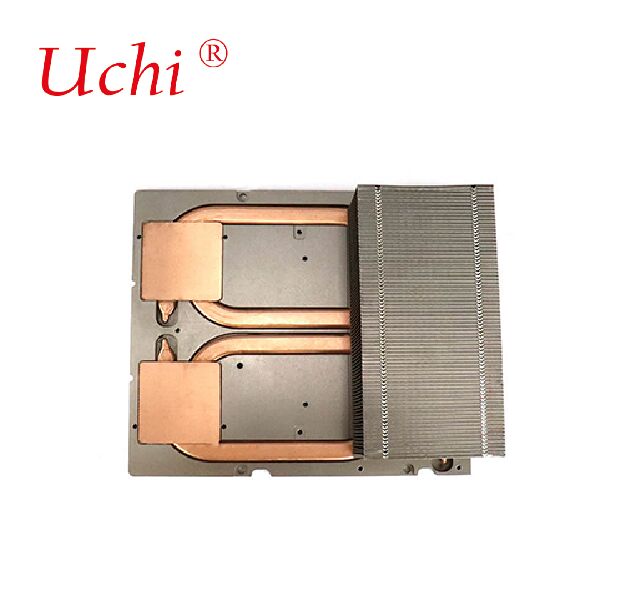

High Advanced Soldering Buckle Heat Sink Complex Heat Sink Module

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | Heat Sink |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | 1300-1500 dollars |

| Delivery Time: | not limited |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Product Weight: | 1.198kg | Process: | Epoxy Bonding |

|---|---|---|---|

| Size: | Customizable | Corrosionresistance: | High, With Anti-corrosion Coating |

| Maxoperatingpressure: | 5 Bar | Treatment: | Passivation Heat Conducting |

| Mountingtype: | Screw Mount | Grade: | Copper |

| Humidity: | 5%~90% | Applicable Industries: | Machinery Repair Shops, Energy & Mining |

| Heat Conducting Powe: | 238W | ||

| Highlight: | soldering buckle heat sink module,complex heat sink module,liquid cooling plate heat sink |

||

Product Description

High advanced soldering buckle heat sink complex heat sink module

Heat Pipe Heat Sink

Heat pipe Heat sink is a new product which can improve many old radiator or heat exchange products and systems by using heat pipe technology. There are two kinds of heat pipe radiator: natural cooling and forced air cooling. It can be used in power electronics, IGBT, transformer, high-power power supply, LED lamps, servers, computers, medical products, etc.The heat pipe heat sink is composed of seal tube, wick and steam passage.When the heat pipe radiator is running, its evaporation section absorbs the heat generated by heat source (power semiconductor devices, etc.) and makes the liquid in the wick tube boil into steam. The steam with heat moves from the evaporation section of the heat pipe radiator to its cooling section. When the steam transfers heat to the cooling section, the steam condenses into liquid. The condensed liquid will return to the evaporation section through the capillary action of the wick on the pipe wall, so as to repeat the above circulation process and continuously dissipate heat.

1. Structural characteristics

It is not an integral extrusion, nor is it a simple scraping tooth

It is composed of multiple parts: bottom plate + dense fins + flow guide structure/liquid cooling cavity.

Fins and bottom plates are fixed by welding/brazing/buckling

The fins are thin, dense and tall, and the heat dissipation area is huge.

Can be made into air-cooled + water-cooled composite structure

Suitable for ultra-high power, high temperature, and space-limited scenarios.

2. Core advantages

Large heat dissipation area, and the heat dissipation capacity far exceeds that of ordinary aluminum extrusion/shovel teeth

Thin fins, high density, good balance between wind resistance and heat exchange efficiency

High structural strength, earthquake resistance and vibration resistance

It can be customized and can be made into special-shaped and high-power modules

Suitable for long-term stable operation of high-power-density equipment

3. Processing technology

Fin stamping/forming

CNC machining of base plate

Fin fastening/plugging/assembly

Vacuum brazing/furnace welding/laser welding

Polishing, stress-relieving, surface treatment

Airtightness/strength test

4. Typical applications

High-power power supply, inverter

New energy vehicle electronic control, motor

Energy storage converter PCS

laser equipment

RF/Microwave Power Amplifiers

Servers, GPUs, AI computing equipment

Industrial transmission, high-frequency equipment![]()

![]()

![]()

![]()

![]()