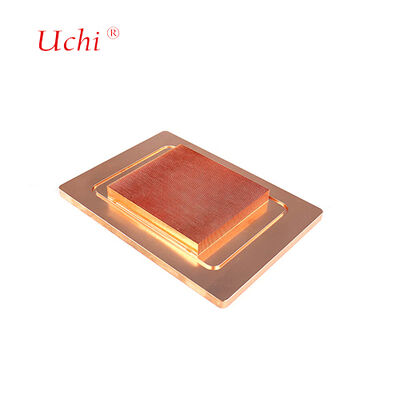

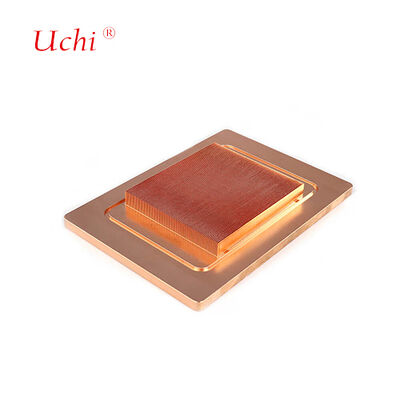

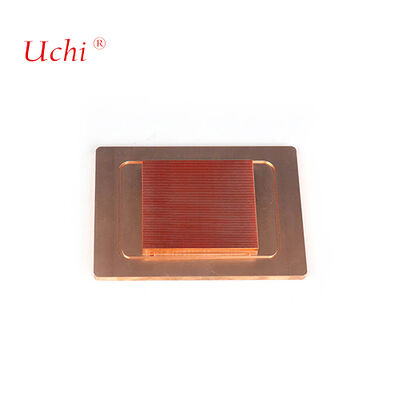

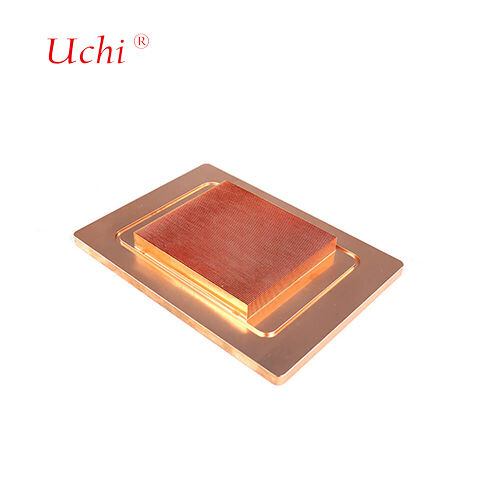

Liquid Cooling System Copper High-Density Fin Heat Sink

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | Uchi |

| Certification: | SMC |

| Model Number: | Aluminum Heat Sink |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100pcs |

|---|---|

| Price: | Negotiable |

| Payment Terms: | T/T,paypal, Western Union,MoneyGram |

| Supply Ability: | 50000000pcs per Month |

|

Detail Information |

|||

| Heat Conducting Power: | 30W | Fan Life: | 50000 Hrs |

|---|---|---|---|

| Material: | Copper 1020 | Size: | 70x70x9mm |

| Weight: | 0.089 Kg | Certification: | ISO9001:2015 ISO9001:14001 |

| Surface Treatment: | PassivationHeat Conducting | Feature: | Reliable Performance And Durable In Material |

| Highlight: | copper liquid cooling system,high-density fin heat sink,liquid cooling plate with warranty |

||

Product Description

Skiving fin technology involves precision machining of copper teeth to create specialized radiator profiles using advanced skiving fin machinery. The resulting skiving fin heat sink features a uniform gap structure formed by mechanical cutting at specific angles, designed specifically for high-power device cooling under air-cooled conditions.

This advanced technology delivers 8-15% higher heat dissipation efficiency compared to conventional heat sinks. With extensive large-scale applications, our skiving fin radiator technology has matured significantly, featuring improved automation levels and remarkable cost and reliability advantages.

- UPS systems

- Base station equipment

- Charging pile infrastructure

- Frequency converters

- Industrial controllers

- Wind power converters

- SVG systems

- LED lighting solutions

High-power LED street lights, factory lighting, stage lighting, and plant growth lights. Extruded heat sinks effectively manage the high heat generated by LED chips, extending lamp life and maintaining stable light efficiency.

High-power density applications including server power supplies, communication power modules, UPS systems, industrial frequency converters, electric vehicle charging stations, and photovoltaic inverters. Extruded heat sinks ensure power semiconductor devices operate within safe temperature ranges, preventing overheating and failure.

Industrial PCs, programmable logic controllers (PLCs), servo drives, and robot controllers. In harsh industrial environments, extruded heat sinks provide reliable heat dissipation for sensitive electronic components, ensuring long-term stable equipment operation.

5G base stations, routers, network switches, and data center servers. As data transmission rates increase, extruded heat sinks provide efficient passive cooling solutions to reduce operating costs.

High-performance desktop CPU/GPU cooling, game consoles, home theater systems, and large-screen TVs. Customized extruded heat sinks optimize heat dissipation efficiency and enhance user experience in compact designs.

Power battery management systems (BMS), motor controllers, and onboard chargers. Extruded heat sinks are critical components ensuring stable operation of power systems under various driving conditions.

Our comprehensive air-cooled equipment portfolio includes: 10 low-temperature solder reflow ovens, 5 baking ovens, 20 automatic solder dispensing units, 3 automatic solder brushing systems, 50 torque-controlled electric screwdrivers, 1 CCD inspection system, 2 fully automatic optical module testing units, 11 multi-station thermal performance testing systems, 4 flatness optical testing units, and various supporting equipment.

We maintain rigorous quality standards with advanced testing equipment including: 1 Coordinate Measuring Machine, 1 projector instrument, 2 water high pressure testing machines, 4 thermal resistance testing machines, and 2 liquid leakage testing machines.

- Prompt response to all inquiries

- Competitive pricing with guaranteed quality

- Efficient production scheduling

- Optimal transportation solutions

- Comprehensive technical support