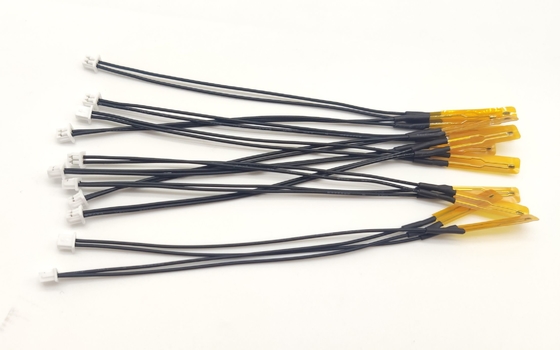

Maximum Power 3.5mW Negative Temperature Coefficient Thermistor UCHI

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | ROHS,ISO |

| Model Number: | IT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000PCS |

|---|---|

| Price: | Negetiable |

| Packaging Details: | Bulk |

| Delivery Time: | 7 working days |

| Payment Terms: | T/T Paypal |

| Supply Ability: | 50000000PCS per month |

|

Detail Information |

|||

| Operating Temperature Range: | -30 ~ 110 °C | Maximum Power Rating: | 3.5 MW : -30 ~ 110 (in Air) (at 25°C) |

|---|---|---|---|

| Dissipation Factor: | Approx. 0.7 MW/°C(in Air) | Thermal Time Constant: | Approx. 5.0 S : 3.5 MW : -30 ~ 110 (in Air) |

| Rated Zero-power Resistance: | 10 KΩ ± 1 % (at 25°C) | Brand: | UCHI |

| Highlight: | 3.5mW Negative Temperature Coefficient Thermistor,Climatic Negative Temperature Coefficient Thermistor,3.5mW NTC Thermistor |

||

Product Description

Negative Temperature Coefficient Thermistor Operating Temperature Range -30 ~ 110 °C

Scope

This specification defines ratings, dimension, insulation, climatic test and mechanical characteristics for MJT type thermistor

Climatic test

Dry Heat

After the test samples are exposed in air at 90±1°C for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

Damp heat

After the test samples are exposed in the humidity of 95% at 40±2°C for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

Cold

After the test samples are exposed in air at –30±1°C for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

Loading

After DC 1mA current is applied to the test samples in the temperature of 40±2°C and the humidity of 95% for 1,000 hours, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

![]()

Mechanical characteristics

1. Resistance to soldering heat

The terminals shall be dipped in to a soldering bath having a temperature of 260±5°C to a point 2.0 mm from the body and then be held there for 5 ±1s, the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

2. Solderability

After dipping the terminal to a depth in a soldering bath of 235±5°C for 2

±0.5s .Approximately 90% of terminals should be covered with solder

uniformly.

3. Free fall

After three times fall to a maple board from 0.75 m high, there shall be no visible damage and the change ratio of the rated zero-power resistance shall be within ±1% of the initial value.

4. Robustness of terminations

After 1N loading weight for 10 ± 1s was applied to the wire terminations, there shall be no visible damage and the change ratio of the rated zero-power resistance shall be within ±1% of the initial

value.

![]()