Home Electrical Appliances Thermal Link GP 115C 3A 250Vac Tinned Copper 70mm

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | UCHI |

| Certification: | UL cUL CCC TUV |

| Model Number: | C3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 7 days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 5000,000,000PCS Per Month |

|

Detail Information |

|||

| Holding Temp. (Th): | Current For 168 H. | Key Features: | RoHS & REACH Compliant |

|---|---|---|---|

| Applications: | Lamps,Transformers,Motors,Batteries,Switched-mode Power Supply ,Home Electrical Appliances, | Customization: | Other Temp.Can Be Customized ,Lead Wires CanbeInsulated,Tinned Copper Wires Or CP Wires |

| Packaging Information: | Carton Size: 330 × 300 × 220 (mm) | Total Length: | 70mm |

| Highlight: | TUV Thermal Link,250Vac Thermal Link,70mm Thermal Fuse |

||

Product Description

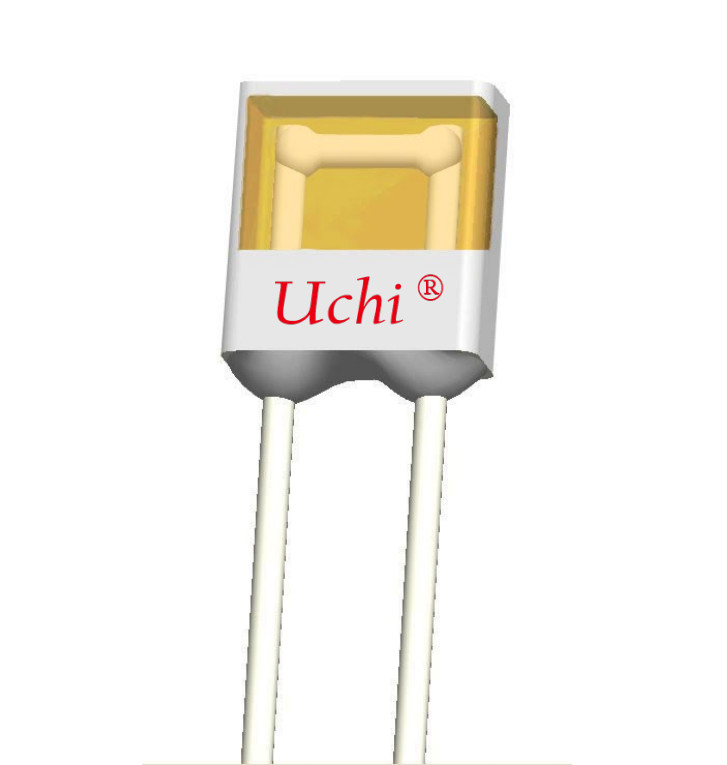

Home Electrical Appliances Thermal-link Radial Shape GP C3 115 °C 3 A 250 Vac,Tinned Copper Wire, Total Length 70mm

| No. | |||

| 1 | 2 | 3 | |

| Part Name | Case | Sealant | Lead Wire |

| Materials | Plastic Case | Sealant Epoxy | Tinned Copper Wire |

![]()

| Dimension (mm) | |

|

L |

5.8±0.5 |

|

W |

5.8±0.5 |

|

T |

2.3±0.3 |

|

L1 |

70±2 |

|

d |

Φ0.54±0.05 |

|

F |

3.7±0.5 |

Soldering

Soldering should be carried out under the soldering conditions listed in table 2.

Table 2 Soldering Time (s)

|

Rated Functioning Temp. Tf (℃) |

Max. Allowable Soldering Time (s) |

Soldering Temp. (℃) |

Show |

||

| Length of Lead Wire (L) | |||||

| 10 mm | 20 mm | 30 mm | |||

| 76~101 | 1a | 2 | 3 |

400 |

|

| 102~115 | 1a | 2 | 3 | ||

| 116~135 | 1a | 3 | 5 | ||

|

136-150 |

3 | 5 | 5 | ||

| 151~221 | 4 | 6 | 7 | ||

|

Auxiliary heat sink fixture is required to avoid Thermal-link cutting off unexpectedly. |

|||||

![]()

Mechanical Connection

Riveting

Suitable for the lead wire diameter (d) of TCO ≥1.2 mm .

Choose small resistivity riveting material and be riveted.

A flexible lead or lead with low resistance should be used to rivet the TCO.

Contact resistance should be minimal, Large contact resistance will lead to higher temp., TCO Functioning in advance

Crimping

Suitable for the lead wire of TCO is flat electrode.

Choose small resistivity crimping material and be riveted.

Crimping process, to ensure that the lead will not be reversed, sealing resin will not be destroyed.

Contact resistance should be minimal, Large contact resistance will lead to higher temp., TCO Functioning in advance.

Please see the specification