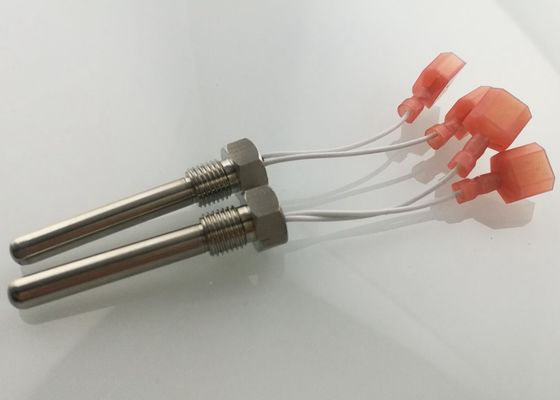

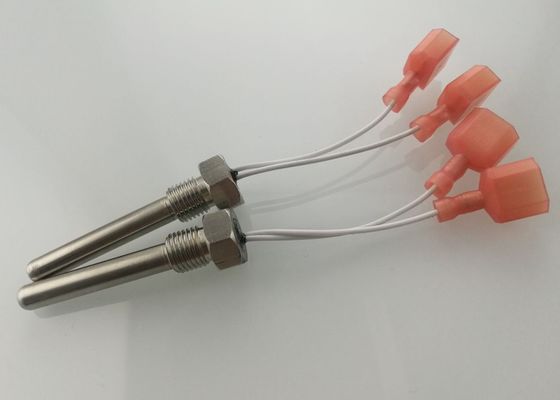

Epoxy Resin Coating Stack Flue Sensor

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | UCHI |

| Certification: | ROHS |

| Model Number: | NSAB1802JD8-650T2I |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500PCS |

|---|---|

| Price: | 6-9 USD / Pieces |

| Packaging Details: | Bulk, unit weight:20g |

| Delivery Time: | 7-10 Days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 150,000PCS Per Month |

|

Detail Information |

|||

| Name: | Stack Flue Sensor | Part Number: | NSAB1802JD8-650T2I |

|---|---|---|---|

| Universal PN: | 42002-0024S | Element: | R200:8KΩ ±5% R150/250:5300K ±3% DDR |

| Cable: | TPEF AWG22*1C 320℃ | Coating: | Epoxy Resin |

| Housing: | JM19105 Φ6.35*54.6+S13+24UNF SUS304 | Terminal: | AMP 250 #22-#18 |

| Operating Temp.range: | -30~+300C | Cable Length: | 65mm |

| Highlight: | pentair heater stack flue sensor,NSAB1802JD8-650T2I,pentair pool heater stack flue sensor |

||

Product Description

Pentair 42002-0024S Stack Flue Sensor Replacement NTC Temperature Sensor For Pool and Spa Heater Electrical Systems

Specification download link : NSAB1802JD8-650T2I SPEC.pdf

Installation method download link : Stack Flue Sensor Insulation.pdf

Description

A stack flue sensor, located on the exhaust elbow of a pool heater, prevents the flue gas output from exceeding 500°F. When this fails, your system will show error codes E05 or E06 to indicate that the stack flue sensor must be replaced.

This replacement stack flue sensor from Optimum Pool Technologies is compatible with Pentair’s MasterTemp, Max-E-Therm, and other Pentair Sta-Rite heaters. It is designed specifically to replace the Sta-Rite heater stack flue sensor.

Location:The Indoor Stack Flue Switch (ES2)/Stack Flue Sensor (SFS) Is Located on the Exhaust Elbow.

Dimension (mm)

![]()

| NO | COMPONENT | MATERIAL AND SPECIFICATIONS | Q'TY | REMARK |

| 2-1 | ELEMENT | R200:8KΩ ±5% R150/250:5300K ±3% DDR | 1 PCS | |

| 2-2 | LEAD WIRE | TPEF AWG22*1C 320℃ | 65mm | (White ) |

| 2-3 | COATING | Epoxy resin | (Black) | |

| 2-4 | HOUSING | JM19105 Φ6.35*54.6+S13+24UNF SUS304 | 1 PCS | |

| 2-5 | TERMINOL | AMP 250 #22-#18 | 2 PCS | (Red) |

| NO | Item | Sign | Test Conditions | Min. | Normal value | Max. | Unit | ||

| 4-1. | Resistance at 200℃ | R200 |

Ta=200±0.05℃ PT≦0.1mw |

7.6 | 8 | 8.4 | kΩ | ||

| Resistance at 150℃ | R150 |

Ta=150±0.05℃ PT≦0.1mw |

/ | 29.65 | / | kΩ | |||

| Resistance at 250℃ | R250 |

Ta=250±0.05℃ PT≦0.1mw |

/ | 2.705 | / | kΩ | |||

| 4-2. | B Value | B150/250 | 5141 | 5300 | 5459 | k | |||

| 4-3. |

Dissipation Coefficient |

σ | In the air | 3 | / | mw/℃ | |||

| 4-4. | Time constant | τ | In the air | / | / | 15 | sec | ||

| 4-5. | Insulation resistance | / | 500VDC | 100 | / | / | MΩ | ||

| 4-6. | Withstand voltage | / | 1500V AC | 5 | / | / | Sec | ||

| 4-7. | Operating temp.range | / | / | -30 | / | +300 | ℃ | ||

Reliability Test

| NO | Item | Technical requirements | Test conditions and method |

| 5-1. | High temp. Test |

DR/R25£±3% |

105±5℃,1000±24 hrs |

| 5-2. | Low temp. tes | -30±5℃,1000±24 hrs | |

| 5-3. | Endure moisture test | Store in environment 65±2℃,90%-95%RH for 1000±24 hrs | |

| 5-4. | Temp. cycle test | Place the sample in -30℃ for 10 min, in 25℃ for 10 min and in 100 ℃ for 10 min. and repeat for 5 times. | |

| 5-5 | Tensile tests |

After tensile test, the sensor should be |

Clamp wire at 50mm away from the inner edge of the connector terminal, then put 10N static tension between terminal and wire for 1min, along axial direction.after the test, check if there is any borken wire, falling off or damage and measure zero-power re. |

| 5-6 | Drop test |

No technical damage. zero power |

Drop the sensor from a meter high through axial and lateral direction to cement floor, each direction for 5 times.then check the appearance and measure zero-power resistance in 25℃ |

| 5-7 | Vibration test | Frequency range:10-500HZ,accelerated speed:10g,frequency sweep time: both X and Y for 30 min.recover for 4 hours after test, visual inspect the appearance of the sensor and measure zero- power resistance in 25℃ |

6.1 In the process of storage and transportation, per stack height is not more than 4 CTN products.

6.2 Available with all transport method, but avoid the rain, snow of direct or indirect leaching and mechanical damage.

6.3 Products should be stored in the temperature of environment - 10 ℃ / + 40 ℃, relative humidity is not more than 80%, environment should not have acid, alkali and corrosion gas or radioactive source.

Attention on operation

7.1 It will bring extra heat and affect testing precision when the current pass through the sensor, With a view to it before selecting sensor.

7.2 When the product moves, the installation must be handled gently to avoid damage caused by pulling the product.

7.3 Product deformation, oxidation and other phenomena, can not be used, so as not to affect the temperature accuracy.

7.4 Excessive temperature variations should be avoided within the operating temperature range.

7.5 Do not use in corrosive gases (such as CO2,NH3,SOX,NOX, etc.) beyond specified conditions.

7.6 Do not use in electrolysis, salt, acid, alkaline and organic solvents beyond specified conditions.

7.7 In the limit temperature, the product can withstand too high or too low temperature shock in the short term, but can not put the product in the limit temperature for a long time, in order to avoid shortening the service life of the product.

If you need any help, please consult our sales staff or engineers, thank you !